Caught In The Loop: My Hyperloop Adventure

A semi-haphazard recollection of my time at college building a hyperloop pod and dreaming of a future where I could ride the hyperloop to work and across continents.

Recently, news broke that Hyperloop One was shuttering its doors1. For those that had worked on the hyperloop at one point or the other, I don’t think it was surprising news. Except probably to those that unreasonably continued to believe that they could usher in a new mode of transportation. It was a cool technology, no doubt. But the business and economic case was full of (to be kind) not-so-easy challenges. And I do actually think it was a good thing that there were determined people who continued to chip away at the mission. Any meaningful progress in the world depends on the unreasonable woman/man.

It brought back memories of the time when I (along with a super talented team of ~30 other undergraduate students from India), got to lead and work on the engineering of a hyperloop pod for the SpaceX Hyperloop Pod Competition in 2017. It was probably the best time of my first 3 years of college before I started Pixxel in the final year. A group of ragtag students with absolutely no experience of building anything close to resembling a hyperloop pod or near it, managed to become one of the 20 finalist teams out of ~2500 global applicants and the only Indian team to do so. With a single digit percentage of resources that other university teams had access to.

The Beginning

My hyperloop odyssey starts when I was but a second year college student in BITS Pilani - one of India’s premier engineering and science universities. One of my seniors from the college there (a super smart and determined Sibesh Kar) had decided to participate in the competition on his own and had also visited the first edition of the hyperloop competition held the year before (2016) - not with any hardware then but an inkling of an initial design. That was the acorn from which everything sprang later.

One day in the beginning of my second year of college, I entered his dorm room and saw that he had scribbled something about the hyperloop in his white board. I hadn’t even been to his room to meet him but rather his roommate. Such is serendipity. When I saw the word hyperloop and some formulae accompanying it, I got to talking about it and decided then and there that I would like to work on it as well with him. And thus began the escapades of the BITS Hyperloop team which grew beyond just the university to become Hyperloop India. The initial days were just putting up flyers across the campus to attract more students to join our team, organising a joining test for interested candidates and setting up the team2. But once we got through the initial screening stage by SpaceX, things got serious and we had to upskill ourselves rapidly to finally deliver a comprehensive design report on which basis, SpaceX would decide who got the green light to manufacture the aforementioned designs and race at a vacuum tube they had built near their HQ in California.

The Growth and the Execution

Now when we decided to get started, my original thinking was that this competition was just a good chance to maybe meet Elon Musk, so while I did take it as serious as any college student would a side project, I didn’t quite take it as serious we would come to take. At one point truly believing that the hyperloop would usher in a new mode of transportation within 10 years. (7 years have passed and spoiler alert: I don’t think it’s happening in the next 3 years.)

Now none of has had any idea how to design a pod that could handle >500km/h speeds, while levitating using magnets in a vacuum tube inlaid with an aluminum track and braking from that insane speed down to zero almost instantly. But we got moving anyway.

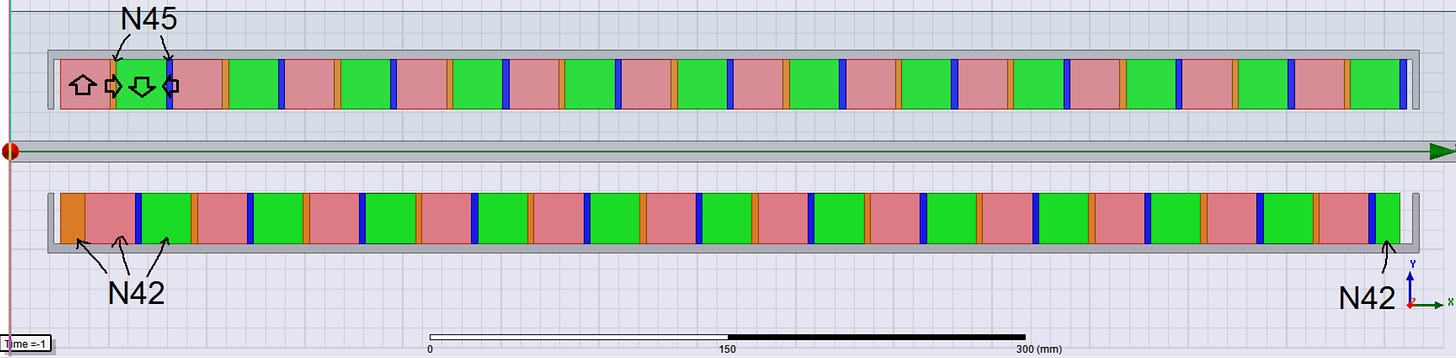

I took up the mantle of the levitation and braking of the pod. Being able to overcome any friction (apart from the removal of air friction due to the vacuum tube) to travel very quickly while at the same time using the same principle to brake almost instantaneously but also at the same time, not so fast as to make (future) people inside the hyperloop nauseous. The approach to both levitation and braking was to build a halbach array for each in different configurations to optimise for floating and braking respectively. A halbach array is an arrangement of really strong (literally hand-crushing) N52 neodymium magnets that magnifies the magnetic field on one side and cancels it out on the other side. The magnified field at the bottom of the pod for levitation creates eddy currents in the aluminum track as the pod moves, which in turn create their own magnetic field, which repel the Halbach array’s magnetic field to levitate the pod beyond a certain lift-off speed.

And so did many other talented folks took up the mantle of a variety of different things - building an aerodynamic structure3 , designing a robust avionics and software stack and so on. How the pod was designed is visualised in the image below.

What also differentiated us from the rest of the teams is that we were building it as a scaled down model of what we envisioned it to look like at a large scale (yes there are many errors and inefficiencies in our original design - after all we were students designing it for the first time!) vs the other teams who were building tiny pods optimised only for speed with no direct way to scale it to a usable system.

Since we couldn’t build this in the middle of a desert where our college campus was, we moved to Bangalore (India’s aerospace hub) for 3 months during the summer holidays to build this vehicle. Challenges were numerous but being naive headstrong students who thought we could get this done anyway (along with a super supportive Bangalore aerospace ecosystem!) helped us get across the finish line and ship a manufactured pod to Los Angeles just in time for the competition weekend.

Getting to SpaceX HQ, briefly meeting Elon and the SpaceX team and learning from the other amazing teams was an experience that gave me enough confidence to pursue any engineering effort I might want to in the future (a direct output of which was to build a satellite constellation at Pixxel4).

The Business Case and the Economics of the Hyperloop

While most of the time was spent on the technology, the team also worked on a business case for the hyperloop in India. Hyperloop India was also one of the 5 finalist teams in the Hyperloop One Global Challenge (yes the same Hyperloop One that recently is closing down).

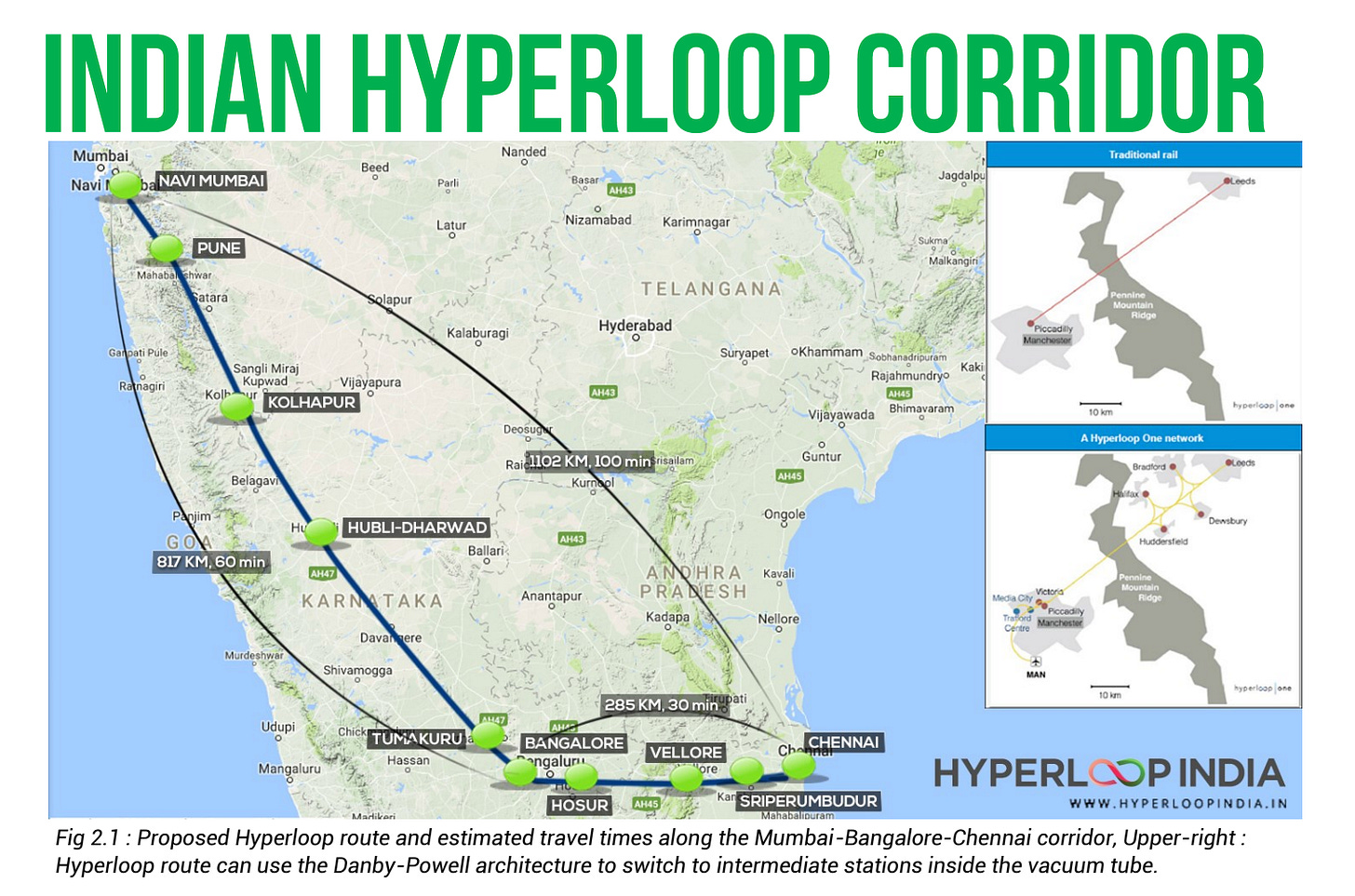

Our proposal was to build a hyperloop corridor in India along the Mumbai-Bengaluru-Chennai corridor hitting other major trade hubs along the way. The idea being that it would start with being a cargo-only hyperloop reducing the oceanic transit time from Mumbai to Chennai to just a few hours through an inland hyperloop route. The idea being that hyperloop would take a few years to reach the safety standards, public confidence levels and meet regulatory approvals for passenger transport. The plan being that a low-stakes cargo system architecture that successfully works along the Mumbai-Chennai-Bangalore route would greatly cement confidence in the future creation of a passenger link along the same track.

There was also an extension of the idea that to truly enable hyperloop to replace other modes of transport would need a similar containerisation that the shipping industry had seen with “the box.”

The idea was that a new container format that slot easily in and out of the hyperloop would make it deeply penetrative and in a couple of decades pay back the investment out into the infrastructure like the shipping container and shipping industry had shown. Of course this was way too optimistic. Getting orgs to change standards that they have been used to for decades before a technology is shown to work at some scale is tough.

The Hyperloop Was Ahead of Its Time or too Late to the Party depending on how you look at it. If money and infrastructure spending was no object, could the hyperloop be technically built? Hell yes. But at way higher costs of any other mode of transport while the others still have to be supported in parallel. Elon Musk estimated the cost for just the first phase of the Los Angeles-San Francisco route at $6 billion, with the entire tube system costing several billion more. Knowing Elon, this number is probably a fraction of what will eventually be required.5 These figures would escalate rapidly due to unforeseen engineering challenges, safety measures, and the cost of acquiring land, even with plans to use existing rights-of-way.

Apart from the obvious fact that the entire system must be virtually air-tight to ensure continuous vacuum, requiring materials and construction techniques that ensure minimal leakage, engineers would have to design joints and materials that can accommodate these changes without compromising the structural integrity or vacuum seal. Expansion loops, sliding joints, and materials with low thermal expansion coefficients that aren’t the norm in other infrastructure might be necessary ballooning the non recurring engineering costs and overall investment needed. For an above the ground concept, the pylons and tubes must be designed to not only withstand everyday wear and tear but natural disasters, terrorist attacks and other emergencies. Not to talk about the literal highs and lows that our planet’s terrain brings with it. For an underground concept, the costs of tunneling would be prohibitively high for anything beyond a city boundary.

The hyperloop promised a future with a leap in speed and efficiency that current technology and infrastructure just aren't prepared to support. Willingness to invest heavily in an unproven system is a hard sell when cheaper, proven alternatives exist.

Potential Viability on the Moon? Interestingly, a hyperloop-like system might make more sense in environments like the moon, where the lack of atmosphere naturally provides the vacuum conditions the hyperloop requires on Earth. Without air resistance, a lunar hyperloop could achieve high speeds with less energy and wouldn't need the extensive and expensive infrastructure to maintain a vacuum. And given there are no alternative modes of transport infrastructure, can start with this in the first place. But to start building exotic levitating pods vs simple tracks for rudimentary trains on a planetary body that humanity is just settling with very little in-situ resources does not make a whole lot of common sense either. But one can dream.

But as I write this, other companies (albeit with much less funding that Hyperloop One) are continuing to work on the hyperloop dream and it might still come to pass that this technology lives to see the light of the day, who knows? All the best to everyone still toiling away.

Lessons Learnt

Apart from the big lesson that sometimes cool technology is just that - cool technology that might not come to fruition or be useful in the real world and that people should work on cool tech regardless of if it seems economically possible or not, the experience taught me a few other things that have been really helpful in life:

Your only limitations are what your ambitions are. How did ~30 under-20 year olds managed to go from Pilani in the middle of a desert in Rajasthan, India to competing in Hawthorne, Los Angeles, USA with some of the world’s best universities? There was a clear audacious goal in mind and no doubt that we would get there. And get there we did.

The only way to build new truly cutting-edge technology is through first principles. When there are no examples or templates to work from, you have nothing else but the laws of physics to fall back to. And more than being a limitation, it is an advantage. With the shackles of tradition broken, you are now free to craft up a new design with only the laws of physics as your constraints.

It all boils down to superhuman determination. There were a thousand problems that came up as we trying to get the pod manufactured and we could have given up anytime and it would have been the easy thing to do. Whether it was getting enough sponsorship to build anything or manufacturing/supply chain woes, the team just kept at it. And more than anything the determination to get it done is why we ended up actually building a functioning prototype.

Age and experience are just numbers; pace of learning and execution are what matter. We were one of the very few teams that was comprised of most if not all undergraduate engineers who had no other comparable hardware experience. Other teams had post graduates, and PhDs with experiences ranging from designing aircraft to electric racing cars. And of course no one in the world had any experience building a hyperloop pod but we got it built anyway. We had a goal. And we had passion. And nothing else really stood in the way. Also personally saw this quote by Margaret Mead actually come to life in front of our eyes - “Never underestimate the power of a small group of committed people to change the world. In fact, it is the only thing that ever has.”

We are taught to evaluate all options and take the right decisions. More often than not in high stakes work, you rather have to take a decision and make it right.6 You will never have all the information you need to take every decision and sometimes you have to use 50/70/80% of information available quickly to take an informed call and go on to make it right. It might not be the most optimal solution but speed matters. Iterations matter. The faster you build, the sooner you will learn new things and the better your future iterations and versions can be. The faster you build, the more energy and passion that people can feed from in the project too generally.

To begin is to be half done - once you get started, the momentum keeps you going. We (or I at least) thought of participating in the competition as a chance to learn a few things and maybe say hi to Elon but ended up being one of the defining experiences of my life. But that momentum took us all the way to not only building cool futuristic technology but also the higher echelons of the Indian government to evangelise that India leapfrog high speed rail directly into a future where hyperloops ply everyday. And that also gave me the confidence that if we could do this, there are no things in the world that a talented, determined and focused group of young people couldn’t do.7

So if you are reading this, and are interested in enabling humanity’s sci-fi future, please go build whatever it is you think will enable that! Our civilisation needs more builders and a hell of a lot of building!

https://futurism.com/hyperloop-one-dead

Interesting side note - the team was split into the three campuses that BITS had in Pilani, Goa and Hyderabad. The Pilani team handled levitation, braking and overall dynamics. The Goa team mainly looked after software and avionics. And the Hyderabad team was responsible for the structure of the pod. The vast distances separating the teams ensured that we had to learn how to work with remote teams before remote work became a norm with COVID. Our discussions ran on Slack, we used video calls and screen shares to discuss the engineering and so on. Program management had to step up to take care of the logistical intricacies. Helped me run a hardware startup during COVID too. The team met for the first times when everyone assembled in Bengaluru for manufacturing the designs after the SpaceX go-ahead.

Vacuum tube doesn’t mean absolute vacuum, some friction starts to creep in at high speeds. Similar to how satellite up as high as 500km face minuscule amounts of atmospheric drag which adds up over the lifetime.

My inexperienced logic early on was that the hyperloop had no how-to guides and no experts to help guide us so it was quite tough to get it built. But satellites have been built for decades and experts are quite a few across multiple countries. I now however realise that useful satellites are sensitive machines that take a lot of care and nourishment to get to orbit and new concepts still require deft engineering. But hey it got me started on Pixxel in the first place, so no complaints.

https://archive.nytimes.com/bits.blogs.nytimes.com/2013/08/15/could-the-hyperloop-really-cost-6-billion-critics-say-no/

This does not mean that one should not gather all information as quickly as one can to take an informed decision. A decision that doesn’t account for first principles thinking can’t be made right if taken with the wrong assumptions or wrong info in the first place. This is for those decisions specifically where there seem to be multiple right pathways albeit with different levels and efficiencies of outcome.

When Neil Armstrong stepped on to the surface of the moon, the average age of engineers at Mission Control was 28.

so well articulated, thanks Awais for writing this :)

Great article, can resonate with most of it when my student team participated in rocketry competitions overseas.